Cost

Duration

$3500 5 days

Recommended Locations

Pre-enrollment is accepted until the minimum student requirement is met. Once enough students have signed up, then we will reach out to process your payment. If minimum enrollment is not attained, we may ask that you consider an alternate date or location. For that reason, the following locations are recommended because they have a low minimum student requirement, or students are enrolled but not yet enough to hold a class:

All Locations

However, if travel is a limitation for you and none of the locations above will work, don't worry. We have several options. And if none of those below suit your needs, feel free to contact us and make a request. We will do everything possible to accomodate. A common request we receive is to do on-site training for companies seeking to get several employees trained at the same time.

About The Course

Designed for every employee in the company. Techniques are condensed down to essential steps necessary to make significant improvement out on the plant floor or in an employee's own area with nothing more than paper, pencil, ruler, and calculator.

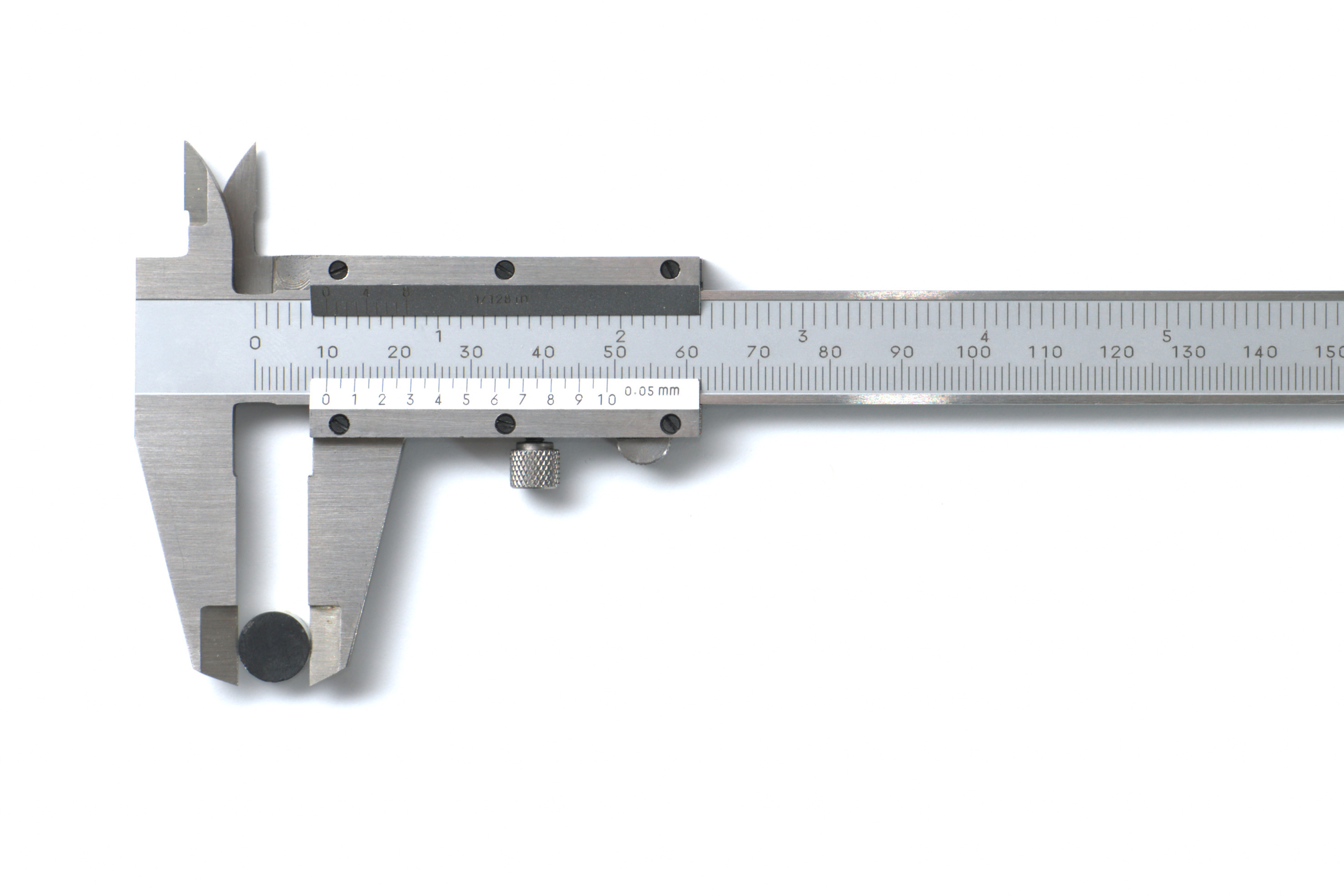

No heavy statistics is used in our Green Belt class. Steps include Six Sigma's traditional DMAIC cycle borrowing from Shainin RedX where needed, and interspersing Lean Manufacturing tools throughout. Specific techniques include: writing work instructions, measurement system analysis through ISO Plot, root cause analysis through Component Swap and basic full-factorial Design of Experiments, Payoff Matrix, Cost-Benefit Analysis, and simplified Statistical Process Control.